Heavy load conveying equipment

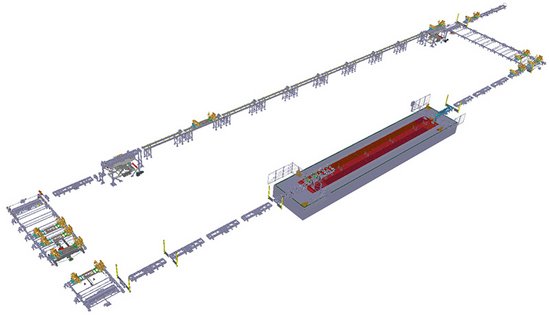

The EBZ heavy load conveying equipment is a transport and positioning system for pallets/carriers usually used in assembly lines for unit and battery assembly.

Pallets/carriers with a weight of up to 5,000 kg (pallet/carrier, unit/energy module, body) can be transported with the system.

Our broad portfolio, consisting of numerous conveying equipment components, can cover a variety of scenarios for pallet/carrier conveying.

Services:

EBZ is a single-source provider of both conveying equipment and geometry pallets. From planning and development to installation and commissioning, EBZ provides all components required for the conveyor system.

Overview of components

High-bay storage systems are used to buffer large quantities of pallets. The pallets are removed from the high bay with a stacker crane and fed into or out of the line. Both components, the high-bay system for buffering pallets and the stacker crane, can be provided by EBZ and adapted to your needs on request.

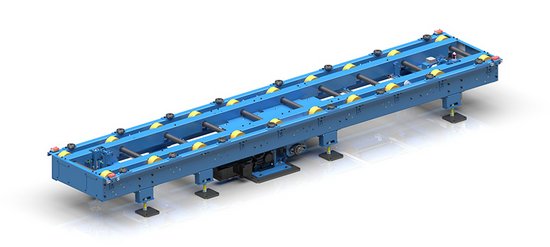

Pallets can be moved transversely on the cross chain conveyor by depositing the pallet on the cross chain conveyor using the roller conveyor scissor lifting unit. The combination of a cross chain conveyor and scissor lifting unit facilitates flexible design of the line.

Specification of the depicted cross chain conveyor:

- Load range: 4,500 kg

- Conveying speed: 35 m/min

Pallets can be fed out and in (e.g. to check the body) using the outfeed car. The car is docked on a roller conveyor element for this purpose and the pallet moved from the line to the outfeed car. The outfeed car carrying the pallet can then be undocked and shifted manually. The pallet can be fed into the line again according to the same principle.

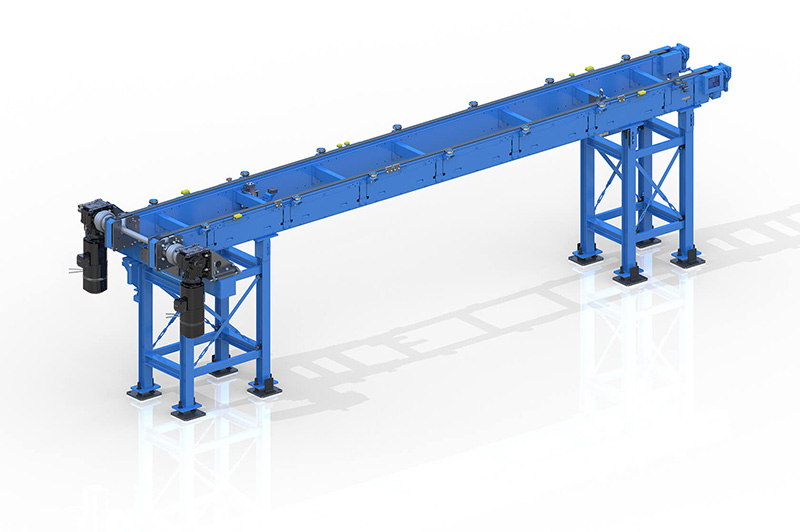

The worker belt enables conveying of the pallet/carrier using an appropriate support and, simultaneously, transporting of the worker on a plastic chain so that he or she can realize working steps while the conveyor belt is moving. Speeds of up to 7 m/min can be achieved. Common widths are between 3.5 m and 4 m. Parameters can be adapted on request.

Specification of the depicted worker belt:

- Conveying length: 30,000 mm

- Belt width: 3,500 mm

- Belt height: 2,000 mm (in pit)

- Loading capacity: 22,500 kg

- Speed: 6.7 m/min

- Conveyor belt: plastic chain

- Number of stations: 6

The overhead chain conveyor enables conveying of the pallet or carrier with ergonomic access to the conveyed material from below. The conveying height, loading capacity and speed can be defined on request.

Specification of the depicted overhead chain conveyor:

- Load range: 5,000 kg

- Conveying length: 7,500 mm

- Conveying height: 1,800 mm

- Conveying speed: 35 m/min

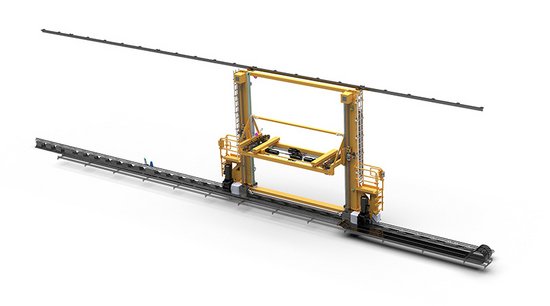

A continuous production line with roller conveyors is not always possible if paths (e.g. for forklifts) cross through the production line. The EBZ shuttle system can be used as a solution for this purpose. The area in front of the shuttle system is clear in the retracted state, meaning vehicles and personnel can pass through. If the pallet or carrier is to be passed onwards, the shuttle system moves into the path and conveys it to the transfer point on the following conveyor technology component.

Specification of the depicted shuttle system:

- Load range: 4,500 kg

- Travel: 10,000 mm

- Travel speed: 0.4 m/s

We are more than happy to offer you other accessories and special solutions on request.

Advantages:

- Conveying of heavy loads up to 5000 kg possible

- Low conveying height of 520 mm (roller conveyor)

- Uncomplicated, robust mechanical structure

- Major flexibility during planning of conveying technology routes due to the broad EBZ portfolio encompassing different conveyor equipment components